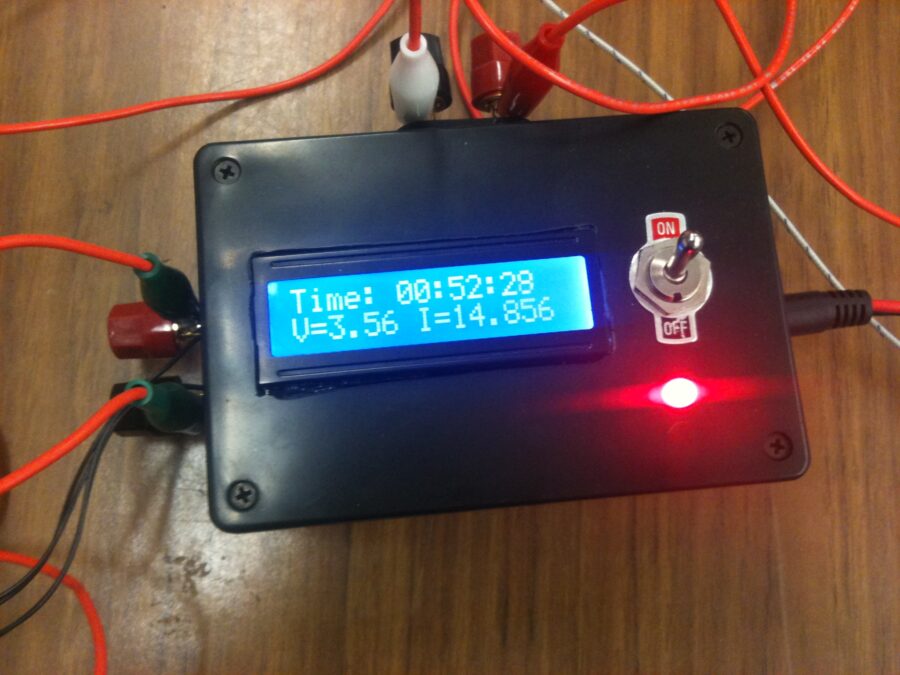

I built the Battery Benchmark Circuit (BBC) v3.0 from scratch to test the custom lithium polymer battery pack I built for the McMaster Solar Car Project. The BBC logs current and voltage measurements to a laptop once per second through an RS-232 connection. We then take that data and integrate the power curve to determine the overall capacity of the cell. Our typical test setup and calculated results can be seen below.

We have been testing the new South Top battery cells in the Solar Car Project’s office at a discharge rate of around 15 amps. As these cells will be installed in the solar car (paralleling two cells to make a single module), this corresponds to a real-world discharge rate of 30A or approximately 3 kW for a 100-volt pack. So far, the results have shown a real-world capacity of 19.5 Ah (ampere-hours) +/- 2%. In comparison, the manufacturer quotes a capacity of 20 Ah +/- 5%.

This is a very promising result that favorably compares against the datasheet. While these cells are rated to deliver a continuous current of 20 A per cell, their 20Ah capacity rating is specified for a constant current draw of 4 A. All batteries have some level of internal electrical resistance, meaning that some power is lost to heat during charge and discharge cycles. Power loss to heat is related to current draw; the higher the current draw, the greater the percentage of power lost to heat. Therefore, it is to be expected that the observed capacity would be lower for higher discharge rates. These tests have shown us that these cells can still deliver near their rated capacity at the higher power levels that can be seen in a solar vehicle.